Research

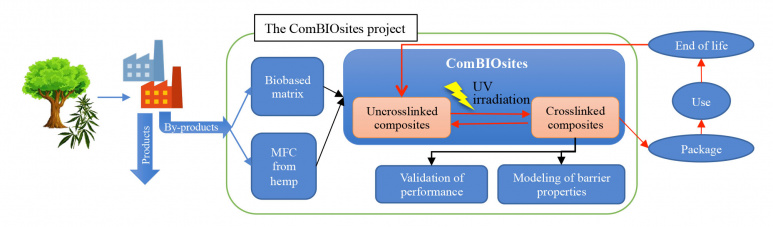

ComBIOsites aims at developing recyclable composite materials for packaging, using bio-based raw materials and environmentally friendly processes, such as photopolymerization. To this aim, we will use microfibrillated cellulose (MFC), and a bio-based prepolymer, functionalized with a reversibly photocrosslinkable group, able to ensure the curing of the polymeric matrix upon irradiation at a given wavelength, and to allow its dismantling upon irradiation at a different wavelength.

MFC films act as a good barrier against gases like O2, CO2 and N2, and are therefore appealing for packaging applications; however,their high hydrophilicity prevents their use in highly humid environments [1]. It is therefore convenient to combine MFC with other polymers in the form of composites. Mixing with water-soluble polymers, as e.g. starch [2] can be favourably achieved in aqueous solution, preserving good filler dispersion, but the composites obtained do not provide water resistance. Crosslinked matrices, as used in traditional composites guarantee high mechanical performances and water and solvent resistance. The uncured prepolymers can have very low viscosity, which allows for solvent-free mixing at room temperature; the cured material becomes insoluble even when prepolymers are water-soluble. However, curing often hinders recyclability. In the ComBIOsites project, recyclable crosslinked matrices will be synthesized. The curing process will be photocrosslinking, which is a green process, solvent-free and with low energy consumption, being performed at room temperature; plus being a fast polymerization process it is attractive for industrial use. The prepolymers will be bio-based and will be functionalized with groups undergoing reversible photocrosslinking, demonstrated with petroleum-based polymers [3]. This opens up the possibility of decrosslinking and thus recycling the composite material. Eventually MFC and prepolymers can be biodegraded or composted, and recent work suggests that the presence of natural fibers may accelerate the biodegradation of crosslinked biopolymers in soil [4].

[1] Li, F. et al., The Potential of NanoCellulose in the Packaging Field: A Review. Packag. Technol. Sci. 28, 475–508 (2015) 7 Hubbe, M. A. et al. Nanocellulose in Thin Films, Coatings, and Plies for Packaging Applications: A Review. BioResources 12, 2143–2233 (2017).

[2] Cheng, G. et al., Comparison of mechanical reinforcement effects of cellulose nanocrystal, cellulose nanofiber, and microfibrillated cellulose in starch composites. Polym. Compos. (2017).

[3] Jellali, R. et al. Photoreversibility and Biocompatibility of Polydimethylsiloxane-Coumarin as Adjustable Intraocular Lens Material. Macromol. Biosci. 17, 1600495 (2017). Nagata, M., Yamamoto, Y. Photoreversible poly(ethylene glycol)s with pendent coumarin group and their hydrogels. React. Funct. Polym. 68, 915–921 (2008) / Störmann, F. et al. Photo-Reversibility of Cinnamylidene Acetic Acid Derived Crosslinks in Poly(ε-caprolactone) Networks. MRS Online Proc. Libr. Arch. 1718, 49–54 (2015) / Tunc, D. et al. Reversible Cross-Linking of Aliphatic Polyamides Bearing Thermo- and Photoresponsive Cinnamoyl Moieties. Macromolecules 47, 8247–8254 (2014).

[4] Silva, A. L. da et al. Cardanol-based thermoset plastic reinforced by sponge gourd fibers (Luffa cylindrica). Polímeros 26, 21–29 (2016)